Here at Horton & Armitage Ltd we have our own in house research and development team. We use the latest design software (Solidworks 2019), to turn an onsite sketch into a fully structured design ready for us to manufacture.

The Lads working on one of our bespoke mild steel hopper sections.

Fabricated vessel, fully manufactured and pressure tested in-house.

Fabricated stainless steel drum for the waste industry.

Mid construction of a multi-story car park manufactured in-house

Designed by our team and manufactured in house.

Fabricated and machined tubes for the energy sector.

Welded Fabrication

Car park sections manufactured in-house then constructed

Fabricated air tanks

Steel building, designed and manufactured to suit customer requirements

Bespoke Stainless steel Gantry

7 Meter Base frame for the Oil and Gas industry

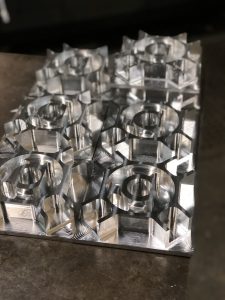

CNC machined components

In-house welding on 1 part of a 3 section waste hopper

Stainless steel tank and mounting frame, Tig welded, leak tested to customer specification

Uprights being fit on site for a complete building manufactured in-house

Table frame manufactured and painted to customer specification

A bespoke louvre damper valve, we were approached by a customer with their requirements. From here we conducted a site visit to measure up. Then designed, tested and fitted on site.

Stainless steel Branch fully manufactured and tested in-house

Fan or Coupling guard manufactured to suit a bespoke base frame

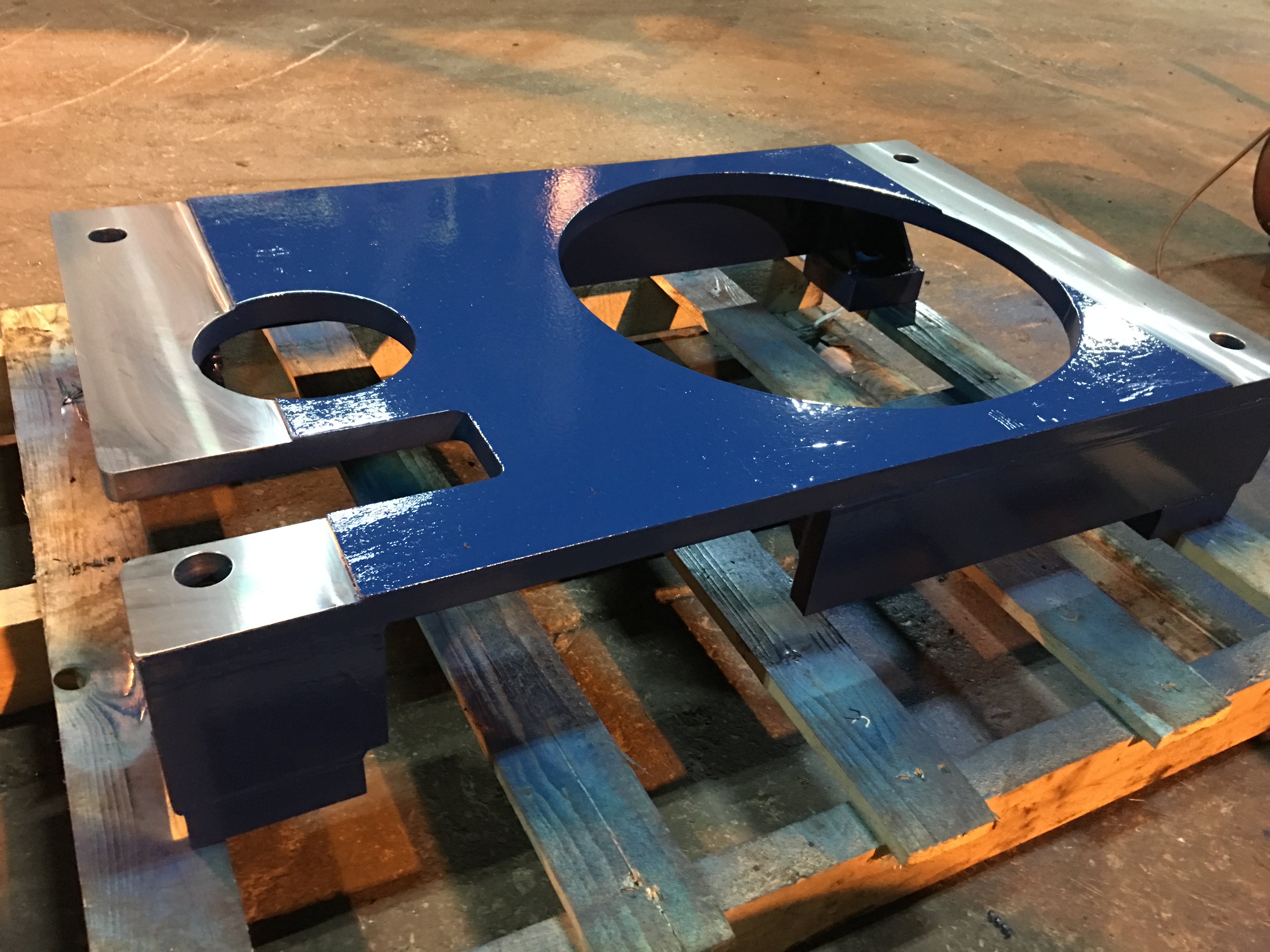

Bespoke motor and gearbox mounting base frame

14 Meter custom drying tunnel, designed and manufactured to suit customer requirements